Space Mission Rescue

SSC scientists and engineers step in to help save a “mission-critical” instrument for the Magnetospheric Multiscale mission

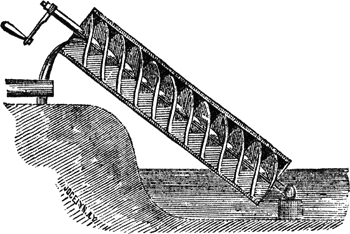

THERE IS SOMETHING DEEPLY SATISFYING in knowing that when a constellation of four spacecraft begin to probe the inner workings of Earth’s magnetosphere in 2014, a mission-critical instrument on board will be based on an elegantly simple concept purportedly invented by Archimedes of Syracuse in the 3rd century B.C.

What’s more, the successful operation of the spacecrafts’ Spin-plane Double Probe (SDP) instruments – which will rely on the principle of the “Archimedean screw pump” to deploy a 190-foot-long, 1/16th-of-an-inch-diameter wire boom into space – will be extra satisfying for scientists and engineers from the Space Science Center who stepped in and rescued the concept during a critical stage of NASA’s Magnetospheric Multiscale (MMS) mission.

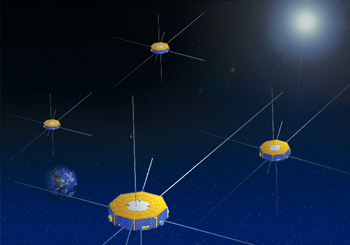

The mission will use Earth's magnetosphere – the comet-shaped magnetic shield that protects our planet from solar and cosmic radiation – as a laboratory to study the microphysics of

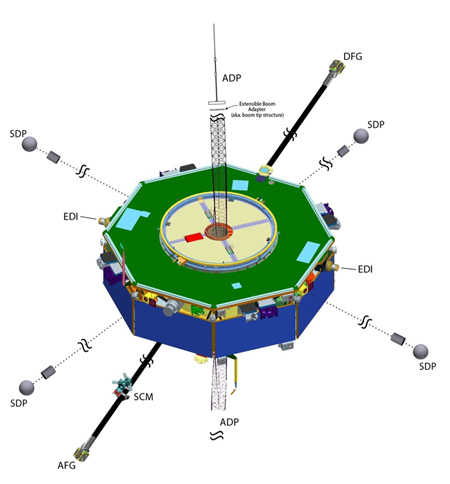

Each MMS spacecraft will have four probes deployed at right angles from the satellite’s spin axis (think of a whirling figure skater with arms outstretched) and each probe will terminate with a sensor designed to measure electric potential. The sensors must be far enough away so that the spacecraft, which will generate their own electrical and magnetic “noise,” do not interfere with the signals from space. Opposing sensors must be deployed simultaneously and to exactly the same distance from the spacecraft for the science experiment to work. Thus, much is riding on the screw pump’s ability to feed out the wire boom in precision fashion and as far away as a 10-story building is high.

UNH is leading an international team of seven institutions for the “FIELDS” instrument suite. UNH scientists, engineers, graduate and undergraduate students have been contracted to help construct two Electron Drift Instruments (EDI) for each of the four MMS spacecraft and build the central electronic controls for all the instruments being built to measure the spectrum of electric and magnetic fields in Earth’s magnetosphere. The FIELDS instrument suite is being centrally managed by UNH.

Last spring, in the process of coordinating the development of this complex, multi-instrument suite, FIELDS project manager John Macri was making monthly trips to the Royal Institute of Technology (Kungliga Tekniska Hogskolan or KTH) in Stockholm, Sweden, which has the contract from the Swedish National Space Board to contribute to various aspects of MMS, including the probe. With each subsequent trip, Macri became increasingly concerned that the probe development was falling behind.

In essence, notes Macri and others on the UNH/MMS team who were also making trips to Sweden, the Swedes had come up with a “very elegant concept” that was not being sufficiently supported from the standpoint of engineering and manufacturing. As a result, they couldn’t keep pace with the demanding schedule. “They have very talented and hard-working people but the resources they were able to dedicate were far too meager for the size of the task,” says Macri.

So in August senior research project engineer Brian King was dispatched to Stockholm to take on project management and systems engineering responsibilities at KTH. In the ensuing months more SSC engineers got involved to bring the work up to speed, among them mechanical engineers Mark Granoff and John Nolin. But in the end, and with a reluctant nod of agreement from Macri, NASA decided lead development of the probe needed to come stateside in order to meet the mission schedule and projected 2014 launch date. Which meant work on the Spin-plane Double Probe was up for grabs.

The Southwest Research Institute (SwRI), lead science institute for MMS, initiated three feasibility studies from organizations that had the expertise and willingness to produce the spin probes. The competition was among a large U.S. research university, a U.S. aerospace company, and UNH. Each had two and a half months to get their ducks in a row before demonstrating their design to NASA.

And so, from the get-go, UNH found itself in third place.

The UNH-SSC team, which in included King, Granoff, Nolin, Ivan Dors, Dave Rau, Mark Chutter, Colin Frost, Jerry Needell, machinists John Levasseur, Aaron Bolton, and Phil Demaine, and UNH principal investigator for the mission Roy Torbert, began by poring over the engineering drawings and dissecting the prototype hardware received from Sweden “to figure out what it would take to make it work in a reliable and robust way,” says Macri. After conducting its due diligence, the SSC team was determined to demonstrate that the Swedish design would work, and the team would do so even in the face of strong competition proposing to use wholly different, already proven concepts.

“At the end of our analysis, we came away convinced that not only could the Swede’s approach be made to work but that it was a remarkably novel and clever idea, and we give them a lot of credit for that,” says Granoff. The novelty of the Swedish design is largely due to its incorporating the principle of the Archimedean screw pump, which allows the wire probe to be deployed with very few moving parts making it relatively simple, compact, and infinitely doable for a group of talented space scientists and engineers with no “mechanism” experience.

But the pressure was on. The team worked weekends and during the Christmas holidays. The much-lauded SSC machine shop remanufactured pieces of the Swedish prototype and built test equipment to put the device through the paces, including thermal tests down to -20 Celsius (-4 degrees Fahrenheit) in a worst-case, space-based scenario. The team repeatedly conducted a four-flight, stairwell experiment in Morse Hall in which the deployer successfully unloaded and reloaded its wire – no loops, no kinks, no wrinkles.

When a skeptical NASA review panel showed up on January 19th the team was so confident it ran a prototype probe in back of the room all day and successfully deployed 190 feet of wire into a canister on the floor (dubbed “the spittoon”) at a rate of 3/8th of an inch per second.

To have proven the Swedish design and fully deployed the probe’s wire boom was an absolute coup for the SSC team, and the mission, for it meant the SDP development could proceed as planned from the beginning; the probes’ integration with all the other complex FIELDS and spacecraft instrumentation would not have to change and, as such, this represented the lowest-risk approach for the mission.

Plus, as Macri and Granoff point out, it meant that the original SDP team would remain intact, albeit in a different configuration.

“What I particularly like about our solution is that it allows us to preserve the team. I didn’t want to lose the Swedes as partners,” notes Macri who has been working with them for more than two years. “They came up with this concept, are a very strong science partner, and they are contributing very important pieces of the SDP and electronics for the mission.”

Key, too, to UNH’s proposal, was the fact that the assembled SDP team included staff from SwRI and the Laboratory for Atmospheric and Space Sciences at the University of Colorado, Boulder who would take on several critical tasks and supplement the SSC talent.

Less than 24 hours after successfully deploying the wire boom for the NASA review team, Torbert got the call. He phoned Granoff. “Well, the dog caught the car,” Torbert reported, “so be in here bright and early tomorrow.”

Be careful what you wish for indeed; just look at the numbers: To populate the four MMS spacecraft and prepare adequate spare units, UNH will build eight highly complex EDI sensors, 18 SDP sensors and four Central Electronics Boxes (CEB). Each EDI sensor contains 14 sensitive analog and digital electronic printed circuit boards; each SDP sensor contains three. Each CEB contains nine boards, two of which are UNH-built and -programmed computers. FIELDS team collaborators provide 15 magnetic field sensors, eight electric field sensors on axial booms and the remaining complement of electronics boards that populate the CEB.

Notes Torbert, “I have never been prouder of our outstanding engineering and research staff. They took on a giant task, never blinked, worked their hearts and minds to the limit, and produced a quality plan that so impressed NASA that the space agency completely changed their stated preconceptions and awarded our team this program. If you wanted to learn about teamwork, this was the ideal example.”

To date, UNH has been awarded just under $69 million from NASA for the mission, including the most recent infusion of $5 million for the Spin-plane Double Probe work. -DS

|

|

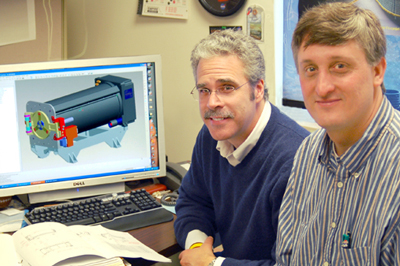

| Space Science Center engineers Mark Granoff and Brian King (at right) with a three-dimensional, solid-model image of the Spin-plane Double Probe instrument. Photo by K.Donahue, UNH-EOS |

The mission will use Earth's magnetosphere – the comet-shaped magnetic shield that protects our planet from solar and cosmic radiation – as a laboratory to study the microphysics of

Each MMS spacecraft will have four probes deployed at right angles from the satellite’s spin axis (think of a whirling figure skater with arms outstretched) and each probe will terminate with a sensor designed to measure electric potential. The sensors must be far enough away so that the spacecraft, which will generate their own electrical and magnetic “noise,” do not interfere with the signals from space. Opposing sensors must be deployed simultaneously and to exactly the same distance from the spacecraft for the science experiment to work. Thus, much is riding on the screw pump’s ability to feed out the wire boom in precision fashion and as far away as a 10-story building is high.

UNH is leading an international team of seven institutions for the “FIELDS” instrument suite. UNH scientists, engineers, graduate and undergraduate students have been contracted to help construct two Electron Drift Instruments (EDI) for each of the four MMS spacecraft and build the central electronic controls for all the instruments being built to measure the spectrum of electric and magnetic fields in Earth’s magnetosphere. The FIELDS instrument suite is being centrally managed by UNH.

Last spring, in the process of coordinating the development of this complex, multi-instrument suite, FIELDS project manager John Macri was making monthly trips to the Royal Institute of Technology (Kungliga Tekniska Hogskolan or KTH) in Stockholm, Sweden, which has the contract from the Swedish National Space Board to contribute to various aspects of MMS, including the probe. With each subsequent trip, Macri became increasingly concerned that the probe development was falling behind.

In essence, notes Macri and others on the UNH/MMS team who were also making trips to Sweden, the Swedes had come up with a “very elegant concept” that was not being sufficiently supported from the standpoint of engineering and manufacturing. As a result, they couldn’t keep pace with the demanding schedule. “They have very talented and hard-working people but the resources they were able to dedicate were far too meager for the size of the task,” says Macri.

So in August senior research project engineer Brian King was dispatched to Stockholm to take on project management and systems engineering responsibilities at KTH. In the ensuing months more SSC engineers got involved to bring the work up to speed, among them mechanical engineers Mark Granoff and John Nolin. But in the end, and with a reluctant nod of agreement from Macri, NASA decided lead development of the probe needed to come stateside in order to meet the mission schedule and projected 2014 launch date. Which meant work on the Spin-plane Double Probe was up for grabs.

The Southwest Research Institute (SwRI), lead science institute for MMS, initiated three feasibility studies from organizations that had the expertise and willingness to produce the spin probes. The competition was among a large U.S. research university, a U.S. aerospace company, and UNH. Each had two and a half months to get their ducks in a row before demonstrating their design to NASA.

And so, from the get-go, UNH found itself in third place.

The UNH-SSC team, which in included King, Granoff, Nolin, Ivan Dors, Dave Rau, Mark Chutter, Colin Frost, Jerry Needell, machinists John Levasseur, Aaron Bolton, and Phil Demaine, and UNH principal investigator for the mission Roy Torbert, began by poring over the engineering drawings and dissecting the prototype hardware received from Sweden “to figure out what it would take to make it work in a reliable and robust way,” says Macri. After conducting its due diligence, the SSC team was determined to demonstrate that the Swedish design would work, and the team would do so even in the face of strong competition proposing to use wholly different, already proven concepts.

|

|

| The principle of the Archimedes screw is at the heart of the Swedish-designed Spin-plane Double Probe providing an "elegant" instrument with few moving parts needed to do its critical job. |

But the pressure was on. The team worked weekends and during the Christmas holidays. The much-lauded SSC machine shop remanufactured pieces of the Swedish prototype and built test equipment to put the device through the paces, including thermal tests down to -20 Celsius (-4 degrees Fahrenheit) in a worst-case, space-based scenario. The team repeatedly conducted a four-flight, stairwell experiment in Morse Hall in which the deployer successfully unloaded and reloaded its wire – no loops, no kinks, no wrinkles.

When a skeptical NASA review panel showed up on January 19th the team was so confident it ran a prototype probe in back of the room all day and successfully deployed 190 feet of wire into a canister on the floor (dubbed “the spittoon”) at a rate of 3/8th of an inch per second.

To have proven the Swedish design and fully deployed the probe’s wire boom was an absolute coup for the SSC team, and the mission, for it meant the SDP development could proceed as planned from the beginning; the probes’ integration with all the other complex FIELDS and spacecraft instrumentation would not have to change and, as such, this represented the lowest-risk approach for the mission.

Plus, as Macri and Granoff point out, it meant that the original SDP team would remain intact, albeit in a different configuration.

“What I particularly like about our solution is that it allows us to preserve the team. I didn’t want to lose the Swedes as partners,” notes Macri who has been working with them for more than two years. “They came up with this concept, are a very strong science partner, and they are contributing very important pieces of the SDP and electronics for the mission.”

Key, too, to UNH’s proposal, was the fact that the assembled SDP team included staff from SwRI and the Laboratory for Atmospheric and Space Sciences at the University of Colorado, Boulder who would take on several critical tasks and supplement the SSC talent.

Less than 24 hours after successfully deploying the wire boom for the NASA review team, Torbert got the call. He phoned Granoff. “Well, the dog caught the car,” Torbert reported, “so be in here bright and early tomorrow.”

Be careful what you wish for indeed; just look at the numbers: To populate the four MMS spacecraft and prepare adequate spare units, UNH will build eight highly complex EDI sensors, 18 SDP sensors and four Central Electronics Boxes (CEB). Each EDI sensor contains 14 sensitive analog and digital electronic printed circuit boards; each SDP sensor contains three. Each CEB contains nine boards, two of which are UNH-built and -programmed computers. FIELDS team collaborators provide 15 magnetic field sensors, eight electric field sensors on axial booms and the remaining complement of electronics boards that populate the CEB.

Notes Torbert, “I have never been prouder of our outstanding engineering and research staff. They took on a giant task, never blinked, worked their hearts and minds to the limit, and produced a quality plan that so impressed NASA that the space agency completely changed their stated preconceptions and awarded our team this program. If you wanted to learn about teamwork, this was the ideal example.”

To date, UNH has been awarded just under $69 million from NASA for the mission, including the most recent infusion of $5 million for the Spin-plane Double Probe work. -DS

by David Sims, Science Writer, Institute for the Study of Earth, Oceans, and Space. Published in Winter 2010 issue of EOS .