ONE YEAR AGO, these pages reported that Space Science Center scientists, engineers, and machinists had pulled off something of an eleventh-hour miracle by rescuing a mission-critical or “Level 1 science” instrument for NASA’s ambitious Magnetospheric Multiscale (MMS) mission. That is, without the Spin-plane Double Probe (SDP) the $1 billion mission would not fly or, more precisely, other aspects would need to be “de-scoped” as science goals were scaled back to deal with the loss. But that was not to be.

The UNH team, which was already knee deep in the design and construction of other MMS components, stepped up to the plate and took over an elegant instrument design that had floundered due to a lack of dedicated engineering resources. After two months of nearly round-the-clock effort they created a working model of the SDP deployer and had it ready to roll the night before NASA officials arrived to give a thumbs up or down.

|

|

|

|---|---|---|

| Senior project machinist Phil Demaine. |

Senior project machinist and shop supervisor John Levasseur. |

Senior project machinist Aaron Bolton. Photos by David SIms, UNH-EOS. |

The thumbs went up, the contract was won, and one year and a whole lot of additional work later, UNH got the go-ahead from NASA to move forward into the “flight fabrication” stage for the 16 probes required for the mission. The team is now in the manufacturing mode, and much of the work is being done in the unassuming, corner machine shop on the first floor of Morse Hall. The shop, manned by John Levasseur, Phil Demaine, and Aaron Bolton, has a long, rich history of machining high-precision parts for the complex space instruments built at UNH for numerous NASA and European Space Agency (ESA) missions.

The four-spacecraft MMS mission will use Earth's magnetosphere – the comet-shaped magnetic shield that protects our planet from solar and cosmic radiation – as a laboratory to study the microphysics of magnetic reconnection, a process in which magnetic fields reconfigure themselves and release enormous amounts of energy. UNH is leading an international team of seven institutions for the “FIELDS” instrument suite. To date, UNH has been awarded over $69 million from NASA for the mission.

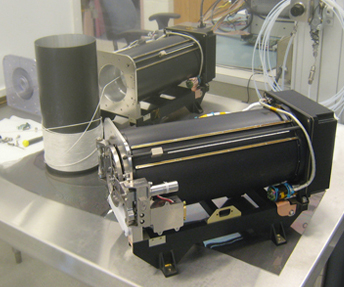

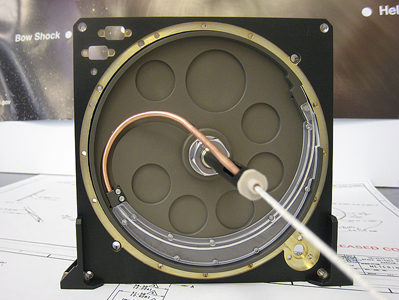

The SDP deployer is designed to ever-so-gingerly pay out 60 meters (192 feet) of spaghetti-like, high-tech cable, at the end of which is an orange-sized metallic sphere that will measure electric potential in the vacuum of space. Each of the four MMS spinning spacecraft has four such deployers positioned 90 degrees apart. So, in addition to an already full plate of MMS tasks, the engineers and machinists now have to construct 16 identical deployers (plus two flight spares and an engineering model) each comprised of more than 100 machined parts, many of which have tolerances in the range of 50 microns – less than the thickness of a human hair.

“The biggest challenge is meeting the close tolerances required of the parts,” says John Levasseur, senior project machinist and a 30-year veteran in the machine shop. The first space mission Levasseur worked on beginning in 1981 was the Compton Gamma Ray Observatory – the second of NASA's Great Observatories launched on April 5, 1991 aboard the space shuttle Atlantis – and on which UNH played a vital role.

Although instruments built for scientific experiments conducted in space are by nature complex and unforgiving (that is, once the spacecraft is up there, things can't be fixed), the SDP deployer is a “mechanism” with moving parts, which makes the job that much more challenging.

Notes Levasseur, “This has never been done before by UNH, that is, building such a complex mechanism for a space mission. The close tolerances are required because all the moving parts of the deployer have to do their job precisely and reliably right out of the starting gate. I had to take the prototype apart piece by piece in order to understand the design.”

Uncharted Waters

The instruments on all the numerous space missions SSC scientists, engineers, and machinists have designed and built over the years have been comprised of static (not moving) parts and make measurements “passively.” Such instruments can generally be “tweaked” via ground command to adjust operating parameters and adapt the instrument to the circumstances it encounters in space.

Not so with the deployer, and taking on the SDP project was in a very real sense double jeopardy for UNH.

“We’re in uncharted waters here,” says SSC senior research project engineer Brian King. “Not only has UNH never built a mechanism before but this type of mechanism has never been tried before, it’s never flown in space.”

The novelty of the deployer’s design is its incorporation of an elegantly simple concept purportedly invented by Archimedes of Syracuse in the 3rd century B.C. Unlike, say, a device that spools wire around a canister like a fishing reel, the Archimedean screw pump allows the wire probe to be deployed with very few moving parts making it relatively simple, compact, and less prone to mechanical error.

But moving parts are obviously more prone to error than those that are fixed. So one of the primary tasks of the UNH-SDP team (which also includes Mark Granoff, Pieter Beckman, Ivan Dors, Colin Frost, John Nolin and others) has been to make sure the instrument’s internal torque monitor accurately senses that the deployment of the 60-meter cable is occurring in smooth fashion and at a steady rate of one centimeter per second with no kinks, no twists, no errors. If the monitor detects the least bit of strain, the deployment is halted and operators on the ground can troubleshoot as needed.

King and others note that the team’s ultimate success with the substantial challenge presented by the SDP deployer project goes well beyond helping ensure a successful MMS mission; it means that UNH has opened a new window of opportunity in its future work building space instruments – mechanisms.

“There are perhaps half a dozen engineers here at UNH who are now far more qualified for this kind of effort in the future than they were a year ago,” notes project manager John Macri. He adds, “And what I think that means is that, in the future, we could propose and pass the raised-eyebrow test for other types of instruments that may have mechanisms, or other wire boom instruments.”

The SSC deployer team did, in fact, pass a raised-eyebrow test when skeptical NASA officials showed up over a year ago to see how an elegant engineering design had been brought to it’s real-world potential. At that point, UNH was in third place in the competition to win the contract to build the deployer. The other two competitors had loads of experience and heritage building instruments like SDP. But in the end UNH won the day and the ensuing year just carried that success forward.

Notes Macri, “We did remarkably well, but we need to acknowledge the advice we were given by people on the outside, in particular that from NASA Goddard where they do lots of mechanisms, and from our colleagues at the Laboratory for Atmospheric and Space Sciences at the University of Colorado in Boulder where they also do some mechanisms.”

And senior research project engineer Mark Granoff notes that project partners at the Royal Institute of Technology (Kungliga Tekniska Hogskolan or KTH) in Stockholm, Sweden, where the SDP design originated and which is still intimately involved in the mission’s scientific objective, have continued to be strong partners.

Says Granoff, “The project’s been a little tricky, but once we understood all the issues and built our engineering models, conducted extensive operational testing across wide temperature ranges and under vacuum conditions, and demonstrated its robustness in vibration testing, we’ve come to realize it’s quite a reliable approach, just as reliable as any other.”

It is a modest summation of what amounts to the equivalent of three years of labor done in hurry-up fashion, in just one year.